Direct Costs of Plant Delivery -- Installed

Affordable Housing has a market price the General Contractor must meet.

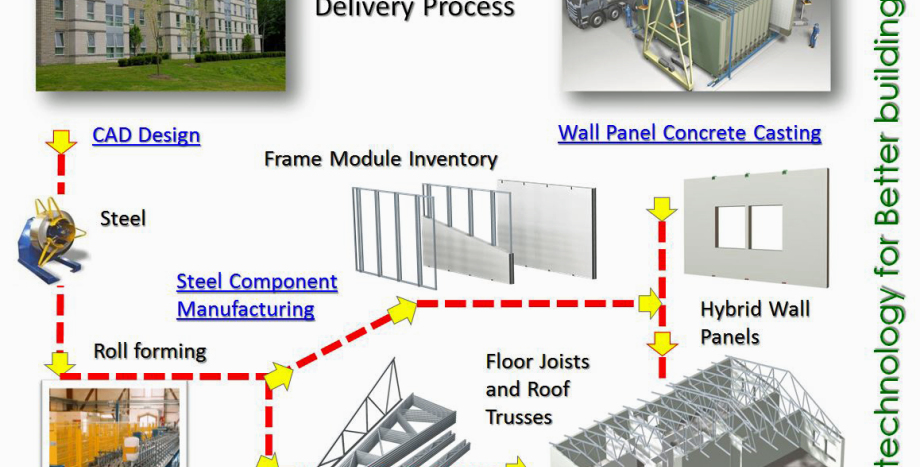

A Whole-House STELLAR Building System has been designed to meet this goal. A Whole-House delivery package from the STELLAR plant includes all the structural components (floors, walls and roof) and partition wall framing for load-bearing and light partition walls.

Partition wall framing can be thickness-adjusted to local door frame sizes -- thus, saving in costs.

In addition, the delivery includes resilient channels for ceiling and hat channels for roof battens -- and for any furring and bracing needs. STELLAR delivers system brackets or provides designs to be produced in the fabrication shop at the plant. Most of the connections at the building site are bolt-fitted. Installation is easy and fast -- with very little training required for installation crews at new building locations.

Calculating plant-based direct costs

- Includes steel material and component assembly, including 3% material waste. Labor cost localized for MENA area and includes 80% operator efficiency (idle time) and 85% line efficiency (tool and coil changes).

- Concrete material, including 10% material waste.

- Brackets are made in the plant’s own fabrication shop or out-sourced from the most competitive supplier in the world

- Labor with burden (benefits – pension, annual vacation/holidays, and unemployment insurance) are shown as 55% of direct labor cost. Of course, these costs must be localized to planned plant location.

- All framing components are Just-in-Time assembled at the plant. In case of low productivity and for higher output (1000-1500 -2 000 units per year), more assembly jigs may need to be acquired.

- Transportation costs from STELLAR plant to the building site are not included. STELLAR recommends that all concrete panels are placed in the plant on (low-loader) pallets and all material handling is per pallet. A low-loader trailer is capable of picking the load and taking it to the building site – the driver is able to be independent in loading and dropping the load at the site. While panels have a weight of about 350 kg per lineal meter, a full volume load becomes possible. This lowers relative transportation costs.

Installation costs at the Building Site

Installation costs use common European (productivity) rates and must be localized considering efficiencies that are possible to achieve. The sample calculation uses 50% localized efficiency. Crew and crane costs must be localized.

The project may be able to use PEIKKO's TENLOC, quick installation camlocks. See the Partner page for more details.

STELLAR earthquake design uses welded mesh loops at vertical joints and the joining space is filled with grout after the panel installation.